ERGONOMICAL – LEVELLER

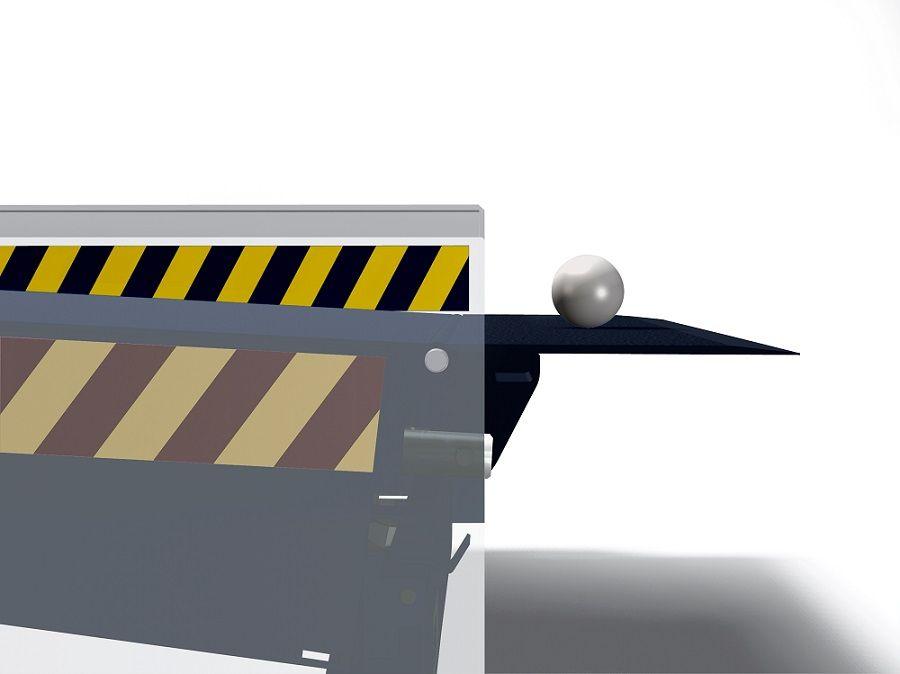

The Stertil Dock Products’ P-Series Hinged Lip dock leveller offers superior ergonomics with the hinged lip which always maintains a horizontal position. No other dock leveller provides such a smooth and simple transition from loading bay to vehicle. The unique and innovative patented parallelogram lip mechanism makes it possible that even a ball can balanced on the lip, without it moving while it is being raised or lowered.

- Less Physical Impact to Personnel

- Horizontal Lip in All Positions

- Highly Efficient

- Optimum Safety

- High Dynamic Capacity of 6 tons

Customer Benefits

No Dirt Build-up Unique Open lip hinge

Closed Rear Hinge

2 Safety Support Legs

Horizontal In All Positions

125 mm tilt

More Stable-1-Hydraulic Cylinder

Horizontal in all positions

The P-Series Horizontal Lip design significantly reduces vibration and noise to ensure a smooth loading and unloading process to minimise the physical impact on personnel and equipment. With a dynamic load rating of 6 tons and an extensive range of platform sizes, the P-Series is suitable for use in almost any loading dock situation. It is especially suitable for pallet trucks with low level ground clearances and is also very suitable for use with 3-wheel forklift trucks.

Improved Efficiency

The severely reduced impact ensures that the risk of damage to goods during loading is minimal. Most importantly, it ensures that loading equipment is subject to less wear and tear, thereby considerably increasing operating life and cutting maintenance costs.

Significant cost savings can also be achieved by reduction of absence among staff due to sickness or injury; this is because they are able to carry out the same work more comfortably and with less physical exertion.

Optimum safety

In case of premature vehicle departure whereby the forklift truck is still on the dock leveller, the automatic panic-stop activates. The leveller in most cases remains in operation even after a panic-stop situation. The emergency stop button on the control box can also be operated manually.

During maintenance, the dock leveller is held safely in position by means of a special maintenance strut. When the leveller is in parked position, it is automatically supported by two cross-traffic safety legs.

Advanced but Simple Control

The dock leveller can be positioned perfectly using the three control buttons, and returned to the parked position using the standard auto park function.

There are several advanced control options which provide additional functions such as door control, shelter control, automated interlock to prevent operation when the dock door is not fully open, and automatic door closure locking until the leveller has been parked correctly.

For every Distribution Centre a Dock Leveller

The P-Series offers numerous possibilities customised to your dock for most efficient use. The length of the platform will primarily be determined by the height difference between the warehouse floor and the expected range of truck beds. Easy installation with the P-Series for both the base-supported frame (PP) in a closed pit, or the suspended frame (PF) in an open pit.

| Dynamic capacity – P Serie Dock Levellers – 6 Tons |

| Lenghts (mm) excluding lip | Working Range (mm)* Above Dock | Working Range (mm)* Below Dock | Frame Height (mm) | |||

| PP | PF | PP | PF | PP | PF | |

| 2000 | 195 | 215 | 254 | 265 | 585 | 700 |

| 2200 | 190 | 220 | 235 | 395 | 585 | 700 |

| 2500 | 270 | 245 | 225 | 335 | 585 | 700 |

| 2800 | 295 | 300 | 215 | 370 | 585 | 700 |

| 3000 | 265 | 270 | 215 | 360 | 585 | 700 |

| 3500 | 360 | 360 | 295 | 295 | 700 | 700 |

| 4000 | 370 | 370 | 280 | 280 | 700 | 700 |

| 4500 | 335 | 335 | 275 | 275 | 700 | 700 |

Platform width (mm) 1750, 1830, 2000, 2110, 2250

* Calculated with a 400 mm lip and 100 mm bumper projection

P = Pit Installation, F = Frame Installation

Technical Specifications

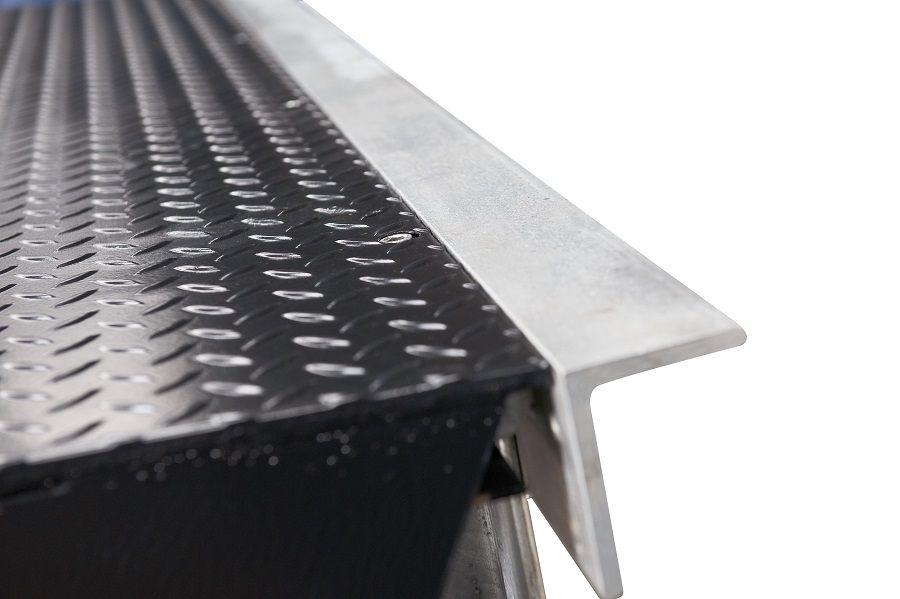

The platform beams and lip are manufactured from high tensile steel (S355J0 / STEEL 52). Both the platform and the lip have a tear plate surface (8/10 mm and 13/15 mm respectively), making them suitable for 3-wheel forklift trucks.

Increased safety with standard 400 mm lip length and 80 mm chamfer on the front edge. The longer hinged lip makes sure that the gap between the vehicle and dock is safely bridged even when dock bumpers are installed.