THE DOCK PLATFORM

It could be the case that there are several different vehicles with varying dimensions at your distribution centre and they all need the same loading bay. Special transport like refrigerated trucks, will be higher for example due to the overhead refrigeration units and at the same time it could be the case that you are receiving goods from tankers, city vans you name it of course all variations are possible. A general rule is to determine the average floor height of both the lowest and the highest loaded vehicle. Also take into consideration the frequency of the different types of vehicles. Make your plans based on the 80:20 rule.

Dock Letter Box

It is not always possible to make an exact estimate of the kinds of trucks that will dock. However, the most common platform height is 1250 mm which is suitable for an average warehouse or trailer park.

Trucks with hydraulic tailboards need a space under the dock leveller, known as a “letter box“. The tailboard slides under the dock leveller into the letter box to allow unrestricted use of the leveller. Letter box slots can be protected by a PVC seal that prevents dirt and debris blowing into the opening. This PVC seal bends away as soon as the truck reverses.

Distance

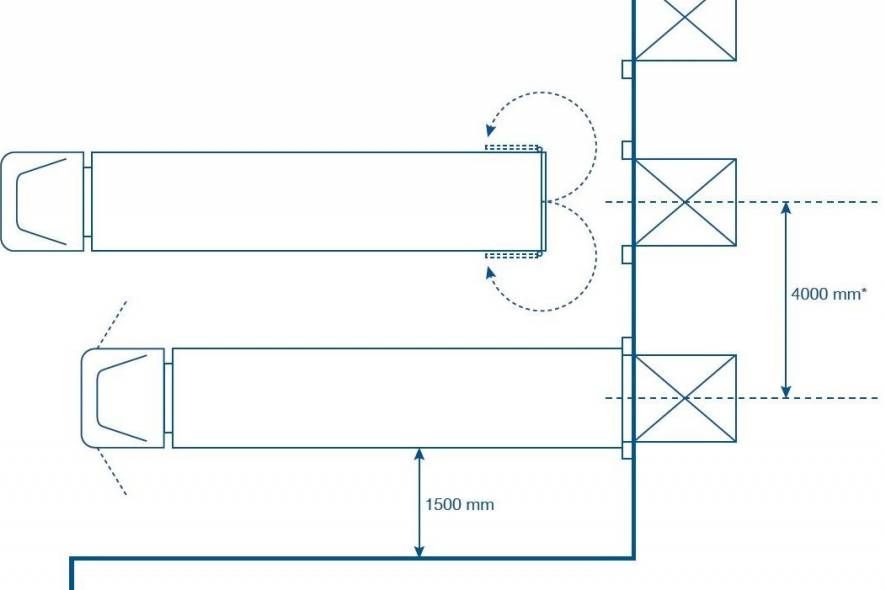

The distance between parked trucks should be big enough to open and close the vehicle’s doors.

Standard loading bays should be at least 3700 mm although, when accommodating wide trucks with open doors, this should be increased to approximately 4000 mm (except for refrigerated and freezer trailers – please refer to the brochure for specific details. The recommended distance between the truck and the loading pit edge is 1500 mm.

The Enclosed Dock

Here the trailer is parked inside the building or sheltered area during loading and unloading but the construction costs are high and there is limited space. Also, a ventilation system is required. However, it provides good protection for goods and personnel.

Dock Houses

A dock house is a construction combining a dock leveller and a dock shelter. It offers a good solution for situations where pit recesses cannot be built, for example in existing concrete bays. Cutting out floors is often an expensive and awkward job. When a dock house can be placed against the existing facade, it can be simply moved after a few years if required. In refrigeration and freezer applications, locating a dock house may involve specific considerations. In order to maintain the extra insulated construction, it is often better to place the entire loading and unloading unit outside the facade.

The dock house can be built with a substructure in steel or concrete framework. The top structure, comprising of hot-dip galvanised profiles, can be clad with uninsulated sheeting or insulated panels. The size of the dock house will depend on the shelter and dock leveller model selected.

The Flush Dock

In this situation, the vehicle reverses up to the back wall of the building. The use of a dock shelter creates a seal between vehicle and the building.

This is the most common installation and the overhead door closes onto the front of the dock leveller.

Door Positioned In front of the Dock Leveller

The door is installed in a custom-made situation and the leveller is positioned further back to allow the door to seal along the front side. If free access is required to the letter box, the door may be closed on an intermediate floor.

Since this would create a greater distance between leveller and truck, the leveller must incorporate a Telescopic Lip. This continuously variable, extendable lip provides a bridge between the building, door and concrete construction.

A Saw Tooth Dock Configuration

In situations where manoeuvring space is limited, a saw tooth configuration may be the best solution. Available manoeuvring space is optimised. Approach roads need to be designed in such a way that trucks can leave in the direction of the angle of the dock.

Vehicles need less manoeuvring space because they are already lined up in the ‘drive away’ direction. Extra building space is required for this saw tooth configuration and useable space between the levellers is limited.