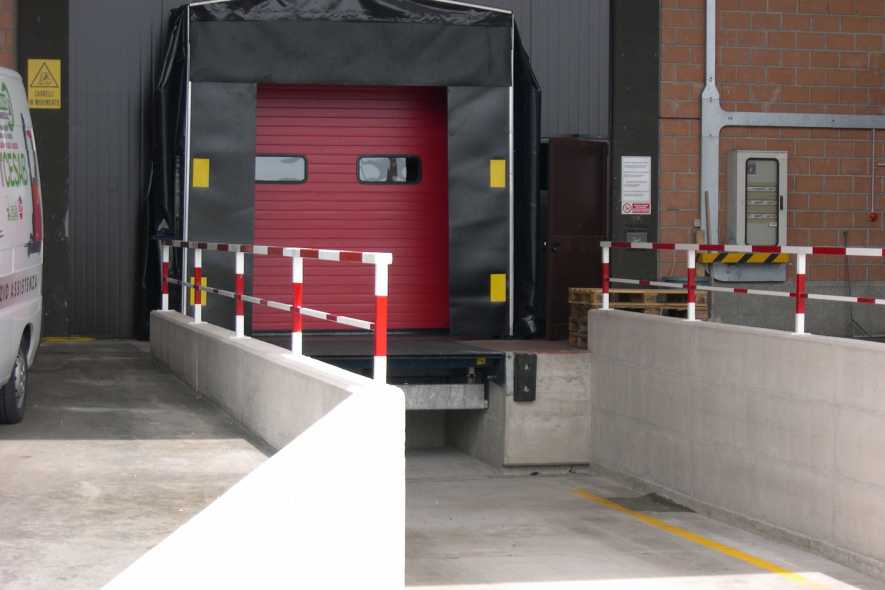

THE LOADING PIT

To reduce the difference in height between the yard and the truck floor, two options are possible:

- Raise the dock floor up to the level of the truck floor

- Create a depressed driveway approach.

For more information on How to design a loading bay download our brochure:

The construction of the loading pit may cause some construction challenges due to unfavourable soil conditions or the ground water level.

A steep decline can create problems because when a lorry is not horizontal during loading or unloading operations, the following problems may occur:

- Loads on trollies can roll-out when the truck’s doors are opened

- Difficult to load and inload on an incline

- Internal handling equipment is under increased pressure

- Rainwater from the vehicle accumulates in the pit

- Dock bumpers under extreme pressure

- Damage to the overhead door and building

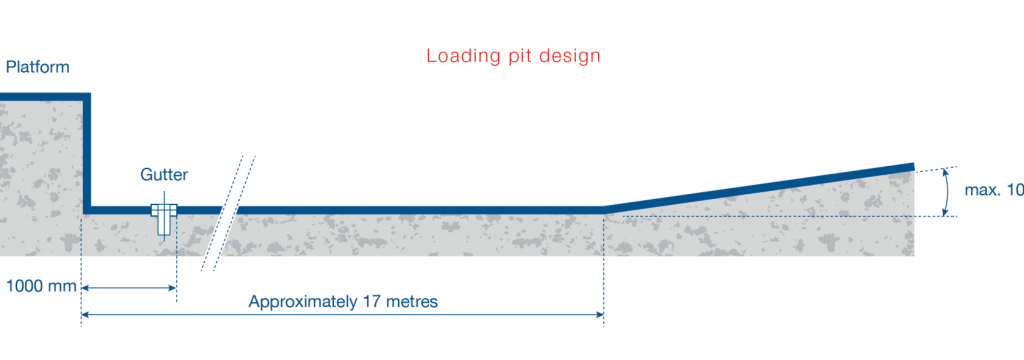

Flat Lane

A flat lane of 16-18 metres may be the solution directly at the front of the dock before the slope begins. A drainage channel is necessary to allow drainage of rainwater. In this situation the vehicle is parked straight which allowing for smooth and simplified loading and unloading.

A GOOD LOADING PIT IS STRAIGHT AND HAS A MAXIMUM GRADIENT OF 10%

The height difference between the straight lane and the road should be bridged with a gradient percentage of a maximum of 10%. When this incline is larger than 10%, problems can arise as trucks drive in and out. In extreme circumstances, a truck cabin and trailer may even hit each other.